Loading... Please wait...

Loading... Please wait...All prices are in All prices are in AUD

Categories

- Home

- Print Techniques?

- Types of Paper

Types of Paper

Types of Paper

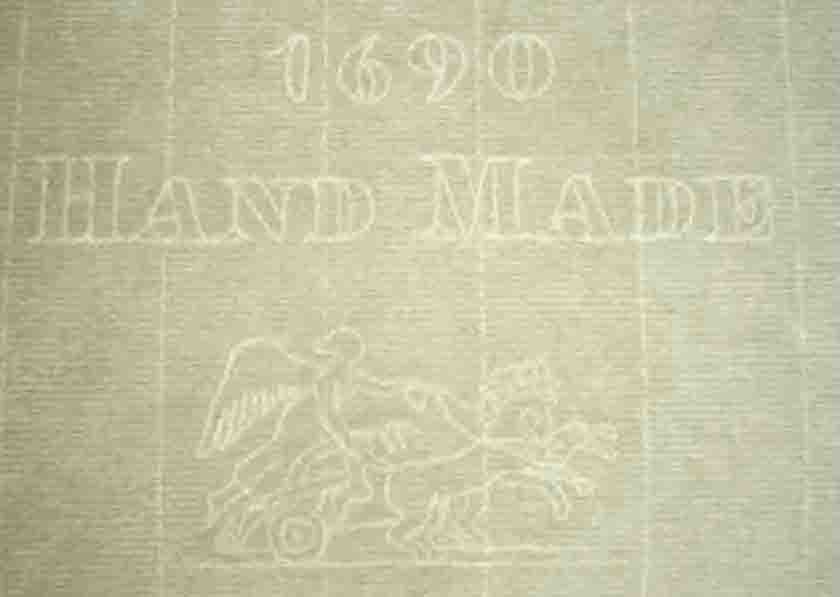

Flax-Hemp 'Laid' Hand-made Paper

Until 1883, over 75-90 % of paper was made with hemp & linen products, sourced from worn-out clothes, curtains, diapers, old hemp fishing lines & tall-ship sails. These items were sold by ship owners to scrap dealers or “Rag ‘n Bone Men”, who in turn sold them for recycling into paper. Rag paper was the epitome of the phrase ‘waste not want not'. Until approximately 1820 all paper was hand-made Laid paper, made by dipping a wooden frame, or deckle, strung with wire, into a fiber suspension slurry. The resulting paper had a “grid” pattern in the sheet, a result of the rag pulp resting against wires stretched across the timber frames as seen in the 1690 sample above. Laid paper is recognized by these wire impressions left in the paper sheet. The strength of rag Laid paper is due to the long length of the fibers as opposed to short wood fibers that were to be used later after 1883. It is believed that Rag paper containing hemp fiber & mulberry, is the highest quality and the longest lasting ever made, surviving up to six hundred years so far.

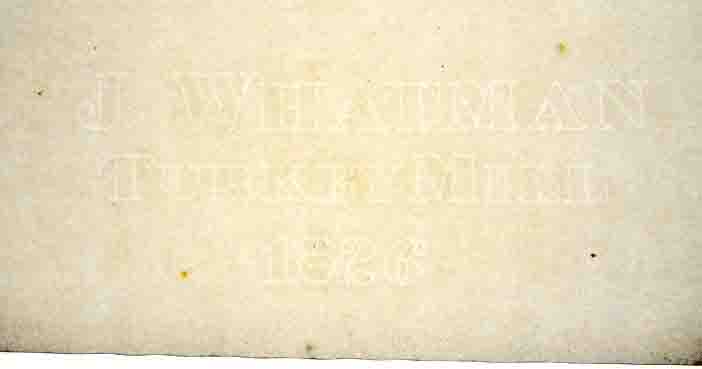

James Whatman’s Flax-Hemp 'Wove' Paper

In 1740, James Whatman, the Elder, is credited with creating, what we now call, Wove paper. However, it took about another half a century to develop the technology to produce a high-quality rag paper in large quantities to compete with the more traditional Laid hand-made product. The first paper making machine was invented in France in the late 1700’s by Nicholas Louis Robert and later developed by Henry Fourdrinier in the 1801. Instead of using labour-intensive wires strung by hand, wove paper was initially made by James Whatman in a timber mold/deckle covered by a very fine woven mesh of thousands of brass wires. It was still handmade but employing the labor-saving mesh screen. This made a much smoother paper sheet. After 1801 the paper-making machines were adopted enabling the paper to be produces in cost-effective rolls. In addition, a roller was added to further smooth the surface of the thicker paper. However, machine-made wove paper was still sourced from hemp/flax, but it lacked the strength of the hand made Laid paper, as the fibers were more uniform laying in the same direction, not over-lapping.

'Wood-Pulp' Paper-Result of supply/demand & demise of sail cloth

The next step in the evolution of paper was the use of hard and soft woods from the vast forests being unlocked by expanding empires. The invention of the steam engine meant ships used less sailcloth, a major source of hemp/flax fiber. As the demand for books grew so did demand for paper to print them on. The Industrial Revolution had created a fiber shortage. During the 1840’s wood pulp was used experimentally in Germany by Friedrich Gottlob Keller. Keller would go on to invent a wood-grinding machine to create wood fibers ideal for use in paper-making from soft-wood conifers. However, it is not until 1883 that this technology became a default source of a new white, cheap & reliable source of paper. Trees will never be scarce...will they? However, it is not until the 1930s that yellowing book pages are noticed, also making the pages brittle. Indeed, rapid aging of books and documents, especially in warmer climates, we now know is caused by an acid in timber called 'lignin'. Once a tree dies it is programed to self-destruct by virtue of an organic polymer, lignin. Book pages, and especially newspapers (traditionally using recycled paper), become brittle and disintegrate due to the acid production of lignin. Public & private libaries, including collectors of memorabilia & sentimental family history are engaging in ongoing battles to rehabilitate wood-pulp items using chemicals to neutralize the acid and bond the cellulose fibers together. By creating a solution to paper supply, a new problem was eventually identified. The term “Inherent Vice” is used for materials that degrade. In lignin fibers that happens, with exposure to UV light, environmental heat & pollutants. To maintain the condition of Wove and Laid paper, and prevent acid deterioration of wood-pulp papers in displayed framed artwork see the Picture Framer’s Guild of South Australia for advice of conservation framing techniques.

© Sandra J. Ker from the Antiquarian Print Gallery in Adelaide 1989-2014, History Revisited 2020- www.historyrevisited.com.au, 0414 790 641